In today’s rapidly evolving technological landscape, the demand for high-precision devices in industries such as healthcare, aerospace, and automotive is increasing at a remarkable rate. Whether it’s medical devices that require strict regulatory compliance or aerospace components that demand the highest standards of performance and safety, the development of such devices requires expertise, precision, and efficiency. Contract engineering has emerged as a critical strategy to streamline the design and development of these complex, high-precision devices.

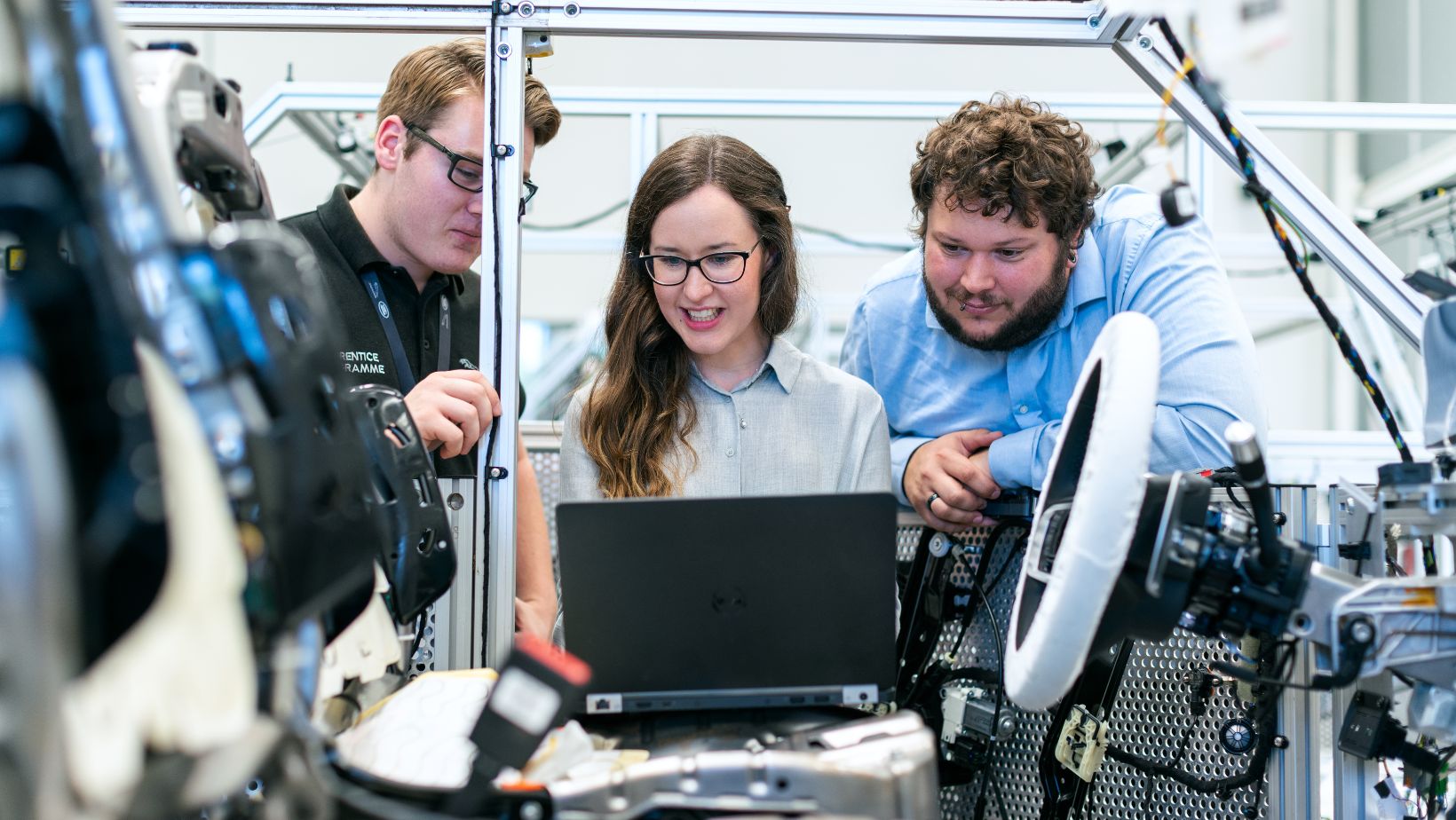

Contract engineering refers to outsourcing specific engineering tasks to specialized firms or independent engineers with the right expertise. These professionals work on a contractual basis, offering businesses access to specialized skills, innovative solutions, and the ability to scale quickly without the overhead of hiring full-time staff. For high-precision device development, contract engineers play an essential role in ensuring that products meet exacting standards while accelerating time to market. Here’s how contract engineering is transforming the development of high-precision devices.

1. Access to Specialized Expertise

High-precision devices often require knowledge in specific areas such as mechanical design, electrical engineering, software development, and materials science. For many companies, hiring full-time experts in each of these disciplines might not be financially viable, especially for smaller firms or startups.

Contract engineers provide a cost-effective solution by offering niche expertise on a project basis. Whether it’s a mechanical engineer to design intricate components or an electrical engineer to develop high-performance circuits, contract engineers bring specialized knowledge and skills to the table. This access to top-tier talent ensures that every aspect of the device’s design and production is handled by professionals with the relevant experience.

For instance, a company developing a medical imaging device might need to work with engineers who specialize in optics and image processing. Rather than hiring multiple specialists full-time, the company can engage contract engineers who possess the precise skill set needed for the task.

2. Faster Time to Market

The speed at which a product can be developed, tested, and brought to market is critical in competitive industries. In high-precision device development, any delay in design or production can lead to missed opportunities, customer dissatisfaction, and increased costs.

Contract engineering can significantly accelerate development timelines. By bringing in experts who are already familiar with the latest technologies and best practices, businesses can streamline workflows, avoid common pitfalls, and reduce the time required for each phase of development.

Additionally, contract engineers often bring a fresh perspective to the table, identifying potential issues early on and offering creative solutions that can speed up development. This approach is especially beneficial in fields where technological advancements are moving quickly, such as medical devices or advanced manufacturing equipment.

3. Cost-Effective and Flexible Solutions

For many businesses, especially smaller ones, cost management is a top priority. Developing high-precision devices can be an expensive endeavor, with substantial costs related to hiring full-time engineers, investing in training, and maintaining a large workforce. Contract engineering provides a flexible, scalable solution that allows businesses to adjust resources as needed without the burden of long-term commitments.

By working with contract engineers, companies can focus their internal resources on core competencies while outsourcing specialized tasks to experts who can deliver results quickly and efficiently. This pay-as-you-go model allows businesses to control costs and avoid the financial strain of building an in-house team for highly specialized projects.

Moreover, contract engineers can be brought in on a project-by-project basis, meaning businesses can scale the team size up or down depending on the project’s complexity and timeline.

4. Improved Innovation and Design Quality

High-precision devices require innovative solutions to meet the ever-evolving demands of their respective industries. Whether it’s creating smaller, more efficient, or more powerful devices, engineers must constantly push the boundaries of what is possible. Contract engineers are often at the forefront of innovation, as they typically work across multiple projects, allowing them to bring cross-industry insights and cutting-edge knowledge to their work.

By collaborating with contract engineers, businesses can leverage the latest design techniques, materials, and manufacturing technologies to improve the quality of their products. Contract engineers often have access to a broad range of resources, including advanced simulation tools, rapid prototyping technologies, and state-of-the-art testing facilities, all of which can significantly improve the quality and functionality of high-precision devices.

In high-tech sectors such as aerospace and medical devices, where failure is not an option, the contribution of contract engineers ensures that each device is designed and tested to the highest possible standards.

5. Compliance and Regulatory Expertise

Many high-precision devices, particularly in regulated industries such as medical devices, pharmaceuticals, and aerospace, are subject to strict compliance standards. These regulations, such as FDA approval for medical devices or ISO certifications, can be complex and time-consuming to navigate.

Contract engineers with experience in these industries bring an understanding of the regulatory landscape, helping companies ensure their products meet the necessary standards. They are often familiar with the specific documentation, testing procedures, and approval processes required for regulatory compliance, reducing the risk of delays due to non-compliance.

By outsourcing to engineers who are well-versed in these requirements, businesses can streamline the approval process and reduce the likelihood of costly mistakes.

6. Scalability and Flexibility for Growing Companies

For businesses that are scaling, the demand for engineering expertise can fluctuate depending on the stage of development. Startups and small companies developing high-precision devices often face challenges when trying to scale their operations. Hiring full-time employees to meet temporary surges in demand can be inefficient and costly.

Contract engineering offers scalability and flexibility. Companies can adjust their team size according to project needs, bringing in more engineers during periods of growth or reducing the team size during quieter times. This allows businesses to remain agile and cost-effective, ensuring that they can scale their operations without unnecessary overhead.

Conclusion

Contract engineering is transforming the development of high-precision devices by offering companies access to specialized expertise, reducing development timelines, cutting costs, and ensuring high-quality design. By leveraging contract engineers, businesses can tap into the latest innovations, maintain regulatory compliance, and scale their operations efficiently—leading to better products, faster time to market, and stronger competitive advantages.